Electroplating Gold Silver Nickel Copper Rhodium

Copper

Copper is the most extensively used metal in electrodeposition with an estimated world-wide consumption of 85,000 tons per year of which 80,000 tons is electroformed foil consumed in the manufacture of printed circuit board laminate.

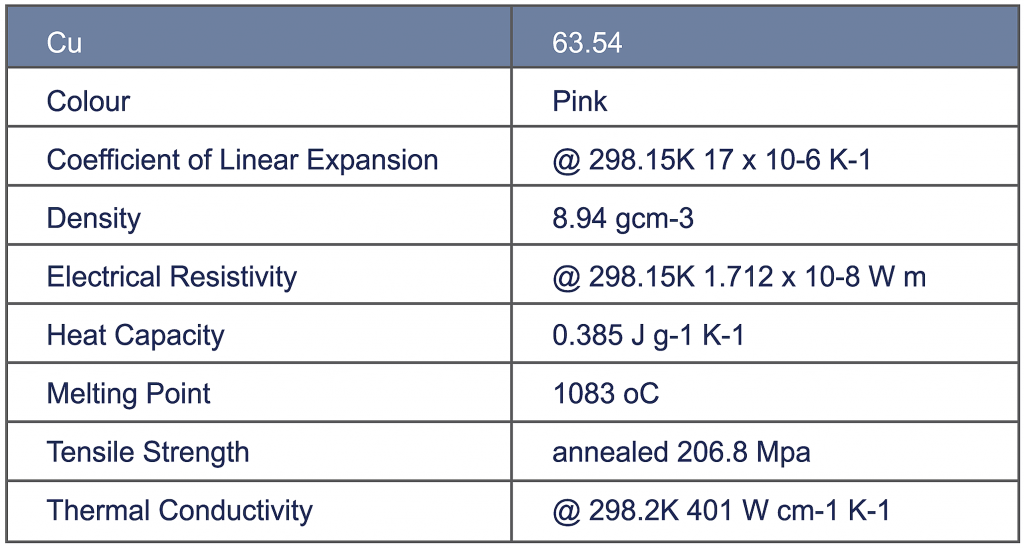

Copper is a soft, pink, ductile metal with high thermal and electrical conductivity.

Decorative copper electroforms were mass produced between 1840 and 1900 in the making of artifacts and printing plates (known as “electrotypes”). The artifacts were most generally reproduced for museum and notable collections in a bid to preserve designs and as educational tools. Although a limited number of copper electroforms are still produced today for the same reasons, the predominant use of copper electroforms is in the manufacture of a wide range of industrial products including spark erosion electrodes, wave guides and cavities for microwave devices.

Electroforming is a particularly useful way to rapidly manufacture short and medium production runs with the major advantage of low cost tooling. BJS copper electroformed components can be trimmed, milled, assembled, finished and then plated with a variety of appealing metals and finishes.