Engineering and Assembly

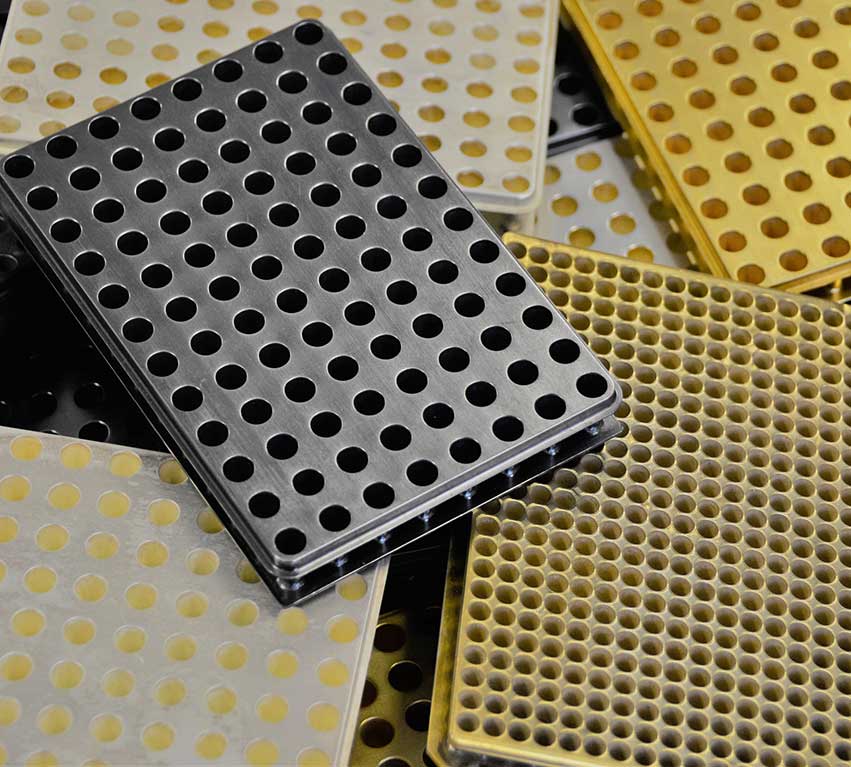

BJS offers a full in-house manufacturing service, joining BJS electroformed component into sub-assemblies by soldering and the welding on turned, cast and sheet metal components, that can be ultimately CNC milled to produce tight tolerances parts that are then finished by polishing, electroplating or chemical colouring to the customer’s requirement.

Industrial applications include silver heat exchange systems manufacture for the biotechnology sector, turbo charger master patterns for the car industry and the fast nickel encapsulation of rapid prototyped parts for F1 teams.

To maintain consistency from batch-to-batch, BJS operates a Coordinate Measuring Machine (CMM) for 3D measurement, as well as X-Ray Fluorescence (XRF) and Ultra-Sonic measuring for electroplating and electroforming thickness determination.

All work is strictly quality controlled using BJS’ BSI audited ISO9001 quality assurance system.